OXFORD, Miss. – C Spire, a diversified telecommunications and technology services company, has expanded its Oxford office, relocating into Insight Park at the University of Mississippi and elevating the Mississippi-based company’s partnership with the university. Supporting economic growth and preparing students for meaningful careers are priorities for both the university and C Spire. Through thisRead the story …

C Spire Opens Insight Park Office

Mississippi-based telecommunications and technology firm expands Oxford office

Summer Program Provides Research Access to Undergraduates

NSF-funded program sponsors students from institutions across U.S.

OXFORD, Miss. – A program at the University of Mississippi School of Engineering is offering undergraduate students an opportunity to pursue research projects this summer. Funded by a $403,106 grant from the National Science Foundation, the Nanoengineering Summer Research Experience for Undergraduates Program enables students to participate in a variety of research, professional development andRead the story …

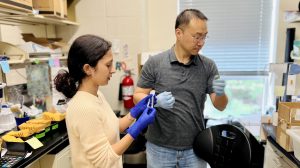

Biology Professor Receives NSF CAREER Award

Yongjian Qiu awarded $1 million to find biological solutions to agricultural challenges

OXFORD, Miss. – The National Science Foundation has awarded University of Mississippi biologist Yongjian Qiu a $1 million grant to further his research into the effects of global warming on crops. Designed to help new teacher-scholars establish their research programs, the NSF CAREER grant will help Qiu conduct more in-depth analysis of the processes that alertRead the story …

FedEx Corp. Expands Strategic Partnership with University

Collaboration supports data science, diversity and leadership programs, and student success

OXFORD, Miss. – FedEx Corp., a longtime industry partner of the University of Mississippi, is advancing that relationship with a major new commitment that promises to have an impact across the university. The expanded partnership established endowed funds to expand the data science program in the Department of Computer and Information Science and support theRead the story …