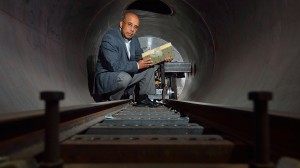

Arunachalam ‘Raj’ Rajendran, UM chair and professor of mechanical engineering, examines a panel fractured during an experiment on blast loading inside the blast tank in his lab at the university’s Jackson Avenue Center. Photo by Robert Jordan/Ole Miss Communications

OXFORD, Miss. – A University of Mississippi professor’s atomistic modeling research that may someday lead to stronger materials for civilian and military applications has been selected as a cover story for the January issue of a prestigious academic journal.

Arunachalam “Raj” Rajendran, chair and professor of mechanical engineering, co-authored “Dislocation evolution and peak spall strengths in single crystal and nanocrystalline Cu,” an article published in the Journal of Applied Physics. Rajendran collaborated with five fellow scientists from the U.S. Army Research Laboratory, or ARL, and the University of Connecticut.

“We performed billions of atoms simulations to understand how pure copper atoms debond due to a strong shock wave and to theoretically calculate material strength at lower length scales,” he said. “This research was initiated by me through the scientists in ARL a few years ago. The JAP liked our paper and requested our permission to use one of the figures from our article on the cover.”

Rajendran explained the nature and impact of the team’s studies.

“When structures fail due to complex operating conditions under extreme environments, the failure process begins at the atomistic levels,” he said. “Ultimately, the degradation of materials at nanometer (one billionth of a meter) and micrometer (an even tinier measurement) levels leads to catastrophic structural failures.

“A fundamental understanding of how materials fail at these length scales will eventually help engineers to design and develop tougher, stronger and more robust materials for a variety of both civilian and military applications.”

The study reported in the journal investigated material failure processes in a metallic system that is subjected to a high-velocity impact. Observing material failure at atomic levels through scientific experiments in laboratories is complex and will require advanced diagnostic techniques with high-resolution instruments.

“We generated a computational model of a nanocrystalline system,” Rajendran said. “With the advent of petaflop computing capabilities, it is now possible to perform research on failure of materials at nano-length scale levels and advance our understanding to macro-length scales to predict failure.”

To model a one-micron cube volume of material, the computer model will require several trillion atoms. For example, a grain of salt contains a billion billion atoms. It is impossible to perform simulations of such systems, even using exaflop computers, some of the most powerful systems available, able to perform a billion billion calculations per second.

“We calculated the dynamic failure strength of pure copper subjected to a strong shock loading (such as the ones generated in any ballistic and blast events) using a state-of-the-art new approach that will not require to model a system with several trillions of atoms,” he said. “By comparing results obtained for six different nano-grain systems, as well as a single crystal system, the computationally determined dynamic failure (spall) strength has been successfully validated in this journal article.”

Though the model was validated for a pure metallic system, it has the potential to model other complex heterogeneous and biological material systems, Rajendran said.

“There is an ultimate need for such computational models toward the design and insertion of new materials that are lighter and stronger for protective and other structural applications to withstand loading generated by extreme environments,” he said. “There are many more research challenges yet to overcome to achieve this ultimate need.”

Alice Clark, UM vice chancellor of research and sponsored programs, commended Rajendran for the latest addition to his list of accolades.

“Dr. Rajendran’s research is a great example of the importance of basic research,” Clark said. “Understanding interactions at the atomic level can lead to practical, real-world solutions. What an exciting achievement for both Dr. Rajendran and the University of Mississippi.”

Rajendran is an emeritus fellow of the ARL, fellow of the American Society of Mechanical Engineers, fellow of the Society of Engineering Mechanics, Distinguished Fellow of ICCES and associate fellow of AIAA. He serves on the editorial boards of the Journal of Computer Modeling, Simulation in Engineering and International Journal of Plasticity.

Rajendran previously served as an associate editor for the ASME’s Journal of Engineering Materials and Technology and Composites Part B: Engineering. He was chair of the executive committee of ASME’s Materials Division in 2009-2011. In addition, Rajendran has been a member of the prestigious in-house basic research review panel for the Corps of Engineers Laboratories during the past three years.

To view the article in the Journal of Applied Physics, go to http://scitation.aip.org/content/aip/journal/jap/119/4.