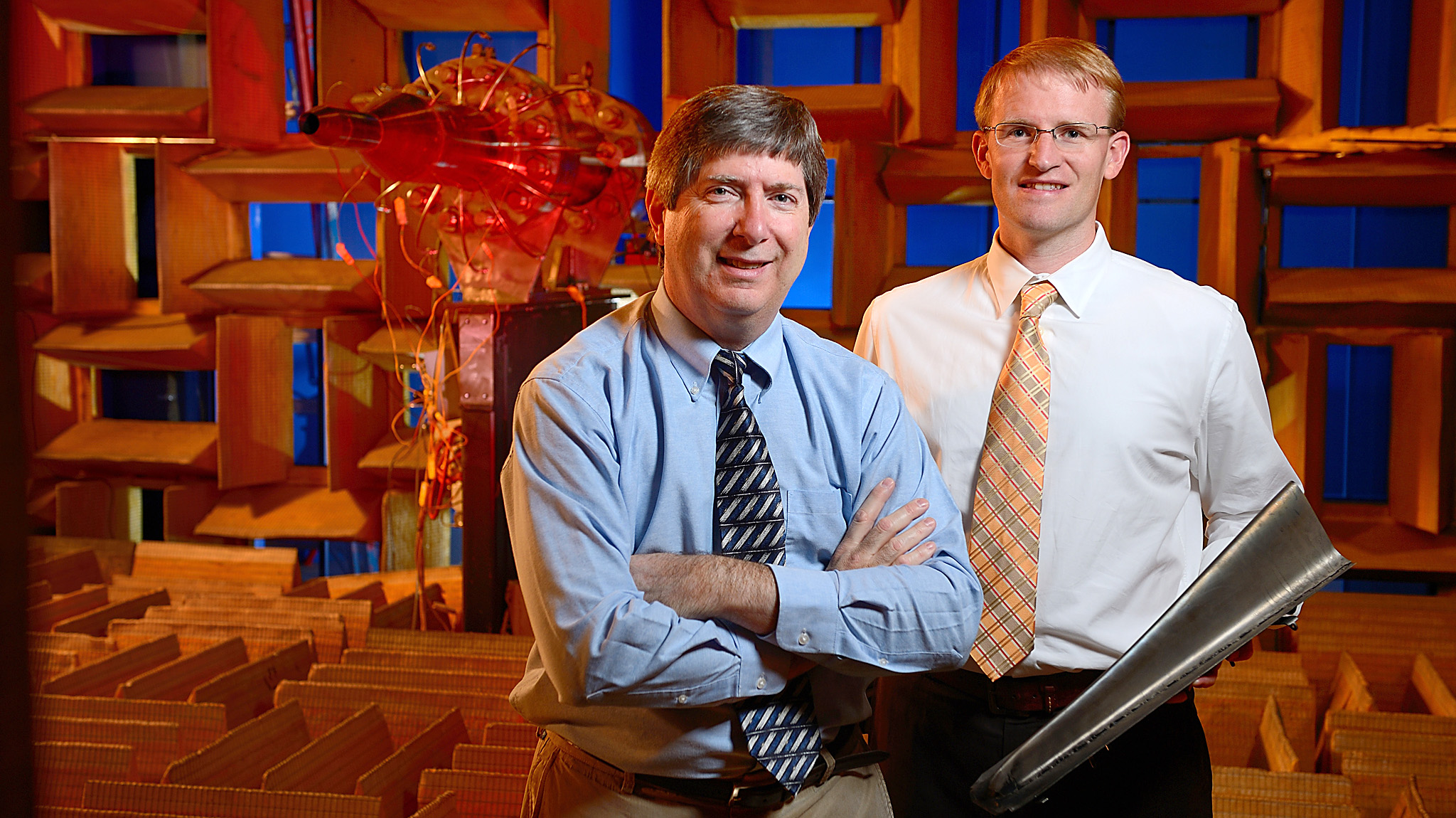

Bernard Jansen (left), a senior research and development engineer, and research scientist Nathan Murray examine an inner seal for a jet nozzle in the Anechoic Jet Laboratory at the National Center for Physical Acoustics. UM photo by Robert Jordan.

OXFORD, Miss. – The roar of high-performance jet engines is ear-piercing, but University of Mississippi researchers at the National Center for Physical Acoustics are studying ways to reduce the shriek of U.S. Navy aircraft.

Noise-induced hearing loss is the Navy’s No. 1 occupational health expense. The economic consequences to the Navy of hearing impairment include lost time, decreased productivity, loss of qualified workers through medical disqualification, military disability settlements, retraining and expenses related to medical treatment, such as for hearing aids.

Nathan Murray and the NCPA Aero-Acoustics Group are under contract with the U.S. Navy’s Naval Air Systems Command, or NAVAIR, to find solutions to reduce the level and intensity of the noise generated by the F/A-18’s exhaust without losing performance and maneuverability.

“The primary goal of the program is to decrease the incidence of noise-induced hearing loss, or tinnitus, and improve situational awareness and communications in noisy operational environments,” said Murray, NCPA research scientist and research assistant professor of mechanical engineering. “As an example, the noise created by the F/A-18 is so loud that no amount of hearing protection can protect sailors from permanent hearing loss, so we must reduce the noise at its source.”

A reduction of the noise by three decibels, about a 30 percent reduction in loudness, would help eliminate permanent hearing loss in affected naval personnel, he said.

NCPA Aero-Acoustics began acoustic suppression studies for F/A-18 fighter jets in 2002 with funding from both NAVAIR and the Office of Naval Research, or ONR. Led by the late John M. Seiner, then-NCPA associate director, the Aero-Acoustics Group made important advances that were patented by the university. Seiner died in late 2010.

“Part of the legacy of Dr. Seiner was his desire to involve students in research with a positive impact on our society,” said Bernard Jansen, senior research and development engineer at NCPA. “His goal was to deal with real-life problems by first attacking them in a scaled lab setting and then implementing the concepts on actual flight vehicles.”

Seiner replaced flat seals on parts of the engine’s exhaust nozzle with corrugated (rounded) ones. The seals keep hot gases from leaking into and damaging other parts of the nozzle when movable flaps, called internal divergent flaps, operate to maintain performance at various air speeds.

Tests showed the new seals reduced the aircraft’s noise by 6.0 decibels, but they had a potentially negative impact on engine performance.

Starting in 2011, NAVAIR provided $2.8 million for the current program, with the goal of a 2.5-3.0-decibel reduction in the noise without any observed reduction in performance. Murray’s group has successfully demonstrated noise reductions of 1.4 decibels (a 15 percent reduction) using a thrust-optimized design that slightly increases thrust. Further optimization may improve the noise reduction.

“These are statistically significant numbers,” Murray said. “Note that decibels are part of a logarithmic scale, so even though the number of decibels reduced is small, it is a big change in the magnitude of the sound.”

The reduction is achieved by installing ripples called “corrugations” inside the F/A-18’s engine nozzle to redirect air flow. The ripples result in significant reductions in eddy mach wave radiation shock noise and screech – the three components of supersonic jet noise, he said.

NCPA researchers are collaborating with both Combustion Research and Flow Technology Inc., of Pipersville, Pa., and AeroSystems of St. Paul, Minn. A partnership with General Electric Aviation has also been formed to ensure the design will work on current and future high-performance jet engines.

“From a scientific perspective, the preliminary results look very positive,” Murray said. “The end goal is to have a design that could be manufactured and installed on naval aircraft. This is government-funded work that we can be proud of, and it’s helping our sailors, improving performance and enhancing efficiency.”

Separately, NCPA, in collaboration with the University of Texas, Auburn University and Combustion Research and Flow Technology Inc., was awarded a $1 million grant under the ONR Jet Noise Reduction program last year.

The ONR-funded collaboration combines time-resolved Particle Image Velocimetry, a technique for visualizing air motion using tiny dust-like particles that allow the measurement of air velocities, with multiple microphones to measure the sound produced by high-temperature jet flows typical of high-performance aircraft. The experiments offer some of the most detailed measurements ever of the noise-producing characteristics of these flows.

“The critical element of the ONR research is to correlate the complex features of jet flows to the noise that is produced,” Jansen said. “Establishing the flow-noise relationship and determining how that relationship changes with nozzle geometry will lead to methods of optimizing performance and minimizing noise.”

The goal is to enable enhanced computational modeling of these complex flows, which will allow future jet noise reduction efforts.

The work is drawing notice. Murray has been appointed to the NATO RTO AVT-198 task group, which focuses on fostering future innovations in noise-reduction technologies applied to military vehicles, and is also a member of the High Noise Source Reduction task force of the Defense Safety Oversight Council.

“I am extremely proud of the work the Aero-Acoustics Group at NCPA is doing,” said James Chambers, interim NCPA director. “They are doing exactly what we need scientists to do in terms of bringing in research funding, mentoring young professionals, teaching students and doing significant nationally recognized work.”

For more information about NCPA and the aero-acoustics research efforts, go to http://ncpa.olemiss.edu/ and http://ncpa.olemiss.edu/aeroacoustics/.