Joey Bonelli, a technician at the U.S. Army Engineer Research and Development Center, subsamples a graphene-enhanced asphalt binder. This binder has potential to increase asphalt strength and longevity. Photo courtesy U.S. Army Corps of Engineers

VICKSBURG, Miss. – Researchers at the U.S. Army Engineer Research and Development Center have started working with multiple applications for graphene, from graphene-infused asphalt and concrete to water filtration systems.

This research has led to the development of a new initiative that brings together top research institutions and experts from the University of Mississippi, Jackson State University, Rice University and the Army R&D center, known as ERDC, to explore graphene’s unique abilities in uses ranging from advanced materials-by-design to self-sensing infrastructure.

Graphene is a form of carbon made of a single layer of atoms. First isolated and described by scientists in 2004, the material is incredibly strong and flexible, and its conductivity lends it to a broad range of applications ranging from manufacturing to electronics to medicine.

The partnership will explore potential military and civilian applications.

“This new initiative will continue a long legacy of ERDC partnering with academia and industry to advance emerging technologies in support of our war-fighters and the nation,” said Robert Moser, ERDC senior scientific technical manager.

This strategic ERDC partnership provides an opportunity to leverage expertise and state-of- the-art materials research from Rice University’s NanoCarbon Center and the UM Center for Graphene Research and Innovation, or CGRI. The center is also working with JSU experts on computational chemistry and synthesis of graphene.

The CGRI conducts graphene research and acts as a bridge with the other research universities, particularly within the state of Mississippi, private industry and other government research and development organizations in the region.

Ahmed Al-Ostaz, UM professor of civil engineering and director of the Center for Graphene Research and Innovation, leads the university’s efforts in graphene research. Photo by Robert Jordan/Ole Miss Digital Imaging Services

“The objective of the project is to strengthen the partnership between the CGRI at UM and ERDC to conduct research in utilizing graphene-based materials and to establish a testing facility at UM that will enrich research capacity in Mississippi, attract industry to the region and enhance collaboration between Mississippi universities, ERDC and broader Army users,” said Ahmed Al-Ostaz, CGRI director.

“We are very excited to the opportunity of collaborating with ERDC researchers on this project and believe that the wide range of engineering applications in both force protection and force projection areas will greatly impact technology and spur innovators to develop new products and processes in areas of national interest.”

James Tour, a professor of chemistry, computer science, and materials science and nanoengineering at Rice University, and colleagues at Rice recently discovered a process called flash Joule heating that produces graphene from any carbon source with low energy requirements and without the need for solvents or purification.

As part of the initiative, ERDC researchers will advance novel flash graphene technology for many potential application areas.

“The flash process produces an unusual kind of graphene, known as turbostratic graphene, that is far easier to bring to applications than graphene traditionally produced in small amounts in a furnace,” Tour said. “Turbostratic graphene consists of misaligned flakes that are more soluble than the more common, or AB-stacked, graphene, which tends to clump in solution.

“Turbostratic graphene is much easier to make, and we are learning to produce it in bulk. We’re confident that our ERDC partners will help us push this process to the limit.”

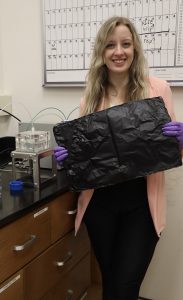

Sarah Grace Zetterholm, a researcher at the U.S. Army Engineer Research and Development Center, displays a graphene mat that can be used as a membrane in water filtration systems or as an absorbent to pull toxins out of water. Photo courtesy U.S. Army Corps of Engineers

Altogether, this initiative will create a regional hub of innovation in partnership with ERDC for novel research and applications in graphene and other low-dimensional materials that could be used to address gaps in advanced materials, composites and manufacturing processes. This can help achieve outstanding military performance, sustainment and readiness across many applications.

“Graphene production and research present a unique opportunity to advance our national defense and infrastructure with next-generation materials,” U.S. Sen. Roger Wicker said. “I am encouraged by the Army Corps’ efforts to bring these opportunities to our state’s skilled students and researchers at University of Mississippi and Jackson State University.

“Such industry and higher education partnerships could serve as a model for Mississippi and the rest of the country for the years ahead.”

U.S. Sen. Cindy Hyde-Smith also touted the potential of the collaboration on the state and nation.

“Advancing graphene technologies and applications could be a boon for our national security, energy future and other areas,” said Hyde-Smith, who helped secure federal funding to support this initiative. “I commend ERDC, Ole Miss, Jackson State and Rice for reaching this point, and look forward to learning more about its progress.”

The research partnership, joining academic institutions and ERDC, promises to benefit the Army in improved force protection and projection capabilities in alignment with the Army’s modernization priorities and priority research areas, along with many spin-off civilian applications ranging from water treatment to resilient infrastructure.