Mastcam-Z views Santa Cruz on Mars. With the help of UM engineers, astronauts could someday construct buildings there. Photo courtesy of NASA

OXFORD, Miss. – As NASA resumes its prepandemic missions to return to the moon and place an astronaut on Mars, some University of Mississippi engineering faculty and students are assisting these efforts through several futuristic research projects.

“A Particle-Based Numerical Framework for Continuum-Level Modeling and Simulation of Titanium Alloys in In-Space Additive Manufacturing,” grant No. 80NSSC19M0053, is the name of one of the NASA-Established Program to Stimulate Competitive Research, or EPSCoR-funded projects.

UM scientists are using both computation and experiments on metals, alloys and cementitious materials found on Earth to study the process of additive manufacturing. Once achieved, these processes could enable future astronauts to build structures and manufacture equipment on the moon and the Red Planet.

“Our research is very fundamental, meaning we have no practical applications at this stage,” said Shan Jiang, assistant professor of mechanical engineering and principal investigator on the project.

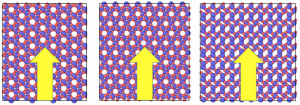

Shan Jiang and his research group work on atomic-level modeling for crystal orientation-dependent wave propagation in silica materials. Silica is a basic component in regolith materials, which are one of the fundamental objects in the UM researchers’ NASA and DoD projects. Submitted photo

“Using metals, alloys and simulated regolith (raw) lunar materials, we can assign numerical values to these, which enable us to produce simulation modeling, make predictions on material properties (such as mechanical and thermal responses), provide advice and give guidelines to NASA.”

Titanium alloys and aluminum, which are very strong, are commonly used to make aerospace equipment such as rockets and space suits. The regolith materials, which tend to be more brittle, come from places such as the Earth’s crust and the volcanoes of Hawaii.

“Using computational techniques, we can take a solid, such as titanium, and describe it as a representative of numerous particles that can reflect its molecular structure,” Jiang said. “Depending upon their size, these particles may range from micro- to even nano-scales.”

The research is funded by NASA jointly through the EPSCoR-Research Infrastructure Development and Cooperative Agreement Notice-Marshall Space Flight Center programs.

Hunain Alkhateb, associate professor of civil engineering, is the PI of “Developing a Novel Method to Bond Planetary Regolith to Form Rigid Structures for Space-Based Habitats,” the second NASA-CAN-MSFC-funded grant (grant No. 80MSFC19M0014). The two are co-principal investigators on each other’s projects. Other co-PIs of these two grants are Sasan Nouranian and Alex Lopez, both associate professors in the Department of Chemical Engineering.

Researchers on the NASA projects have two major goals. The first is to develop a numerical formula that moves the modeling and simulation of in-space additive manufacturing titanium from almost microscopic to actual size scale. The second goal is to explain how materials found on the moon’s surface might interface with transported materials from Earth and be used in building structures on the moon.

“So far, we’ve established an integrated computational framework to explore the atomic-level sintering (fusing materials using laser beams rather than flames) mechanisms of metals/alloys,” Alkhateb said.

“We’ve successfully made use of our proposed procedure to study and optimize the additive-manufactured products with consideration of three types of metal/alloy. Based on these outcomes, we are currently establishing the large-scale (multimillion-atom) molecular dynamics modeling and simulation.”

Graduate and undergraduate students have been involved in the NASA research. Jiang trained and supported senior civil engineering major Ronald Smith of Meridian on the NASA-EPSCoR project to perform some nanoparticle laser sintering research. Smith applied for a 2019 NASA summer internship and later received a job offer in the U.S. Army Engineer Research and Development Center.

Birendra Chaudhary of Nepal graduated in 2020 and entered the Ph.D. program at the University of Rhode Island.

Alkhateb is training and supporting mechanical engineering junior Elisha King of Durham, North Carolina.

Other students involved include Huadian Zhang of China, a mechanical engineering doctoral student who is working on modeling and simulations of titanium-aluminum alloy nanoparticle stacking during laser additive manufacturing.

Ellie Dickens of Vancouver, Washington, is another senior mechanical engineering major working on simulating nanowire structures made of single-crystal titanium nanoparticles prepared by selective laser sintering techniques. Dickens was a co-op intern at NASA-Marshall Space Flight Center this spring and is expected to be back on the project on the UM campus in the fall.

“Engineering undergraduates benefit a lot from this project,” Jiang said. “Our Additive Manufacturing for Research and Education Cluster team successfully recruited, trained and is currently training over 15 undergraduate students within STEM disciplines to pursue academic or industrial careers in the areas of interest to the NASA space program.”

The PI and co-PIs also engaged in outreach activities in local schools including presentations and demonstrations of NASA-related additive manufacturing for the STEM classes in the Oxford School District.

Started in 2018, the NASA-EPSCoR grant has been funded for three consecutive years at a level totaling $150,000. The NASA-CAN-MSFC grant has a funding level of about $100,000. A third proposal, “Lunar Launching Pads Conceptual Design,” has a pending grant under the same program and is expected to be continually funded for another $100,000.

A separate but related three-year project was recently funded by the U.S. Department of Defense-U.S. Army Corps of Engineers at a level of $225,000. “Large-Scale Molecular Dynamics Study of Mechanical Properties and Deformation Mechanisms of Soil Minerals Interacted with Water and Biopolymers,” grant No. W912HZ2020042, partially relies on the numerical platform developed via the NASA projects.

Jiang and his research group are studying the mechanical properties and fundamental mechanisms of deformation in soil minerals.

“These minerals are subjected to both common and extreme loading conditions via simulations,” Jiang said. “Our team also aims to shed light on the effects of humidity and humus substances on soil minerals by investigating the surface interactions among water molecules, biopolymer (living organism) macromolecules and mineral materials.”

For more about NASA’s “Journey to Mars” program, click here. The NASA Mississippi Space Grant program and Mississippi NASA EPSCoR program are funded by training grants from the NASA Office of STEM Engagement.